Tap to explore

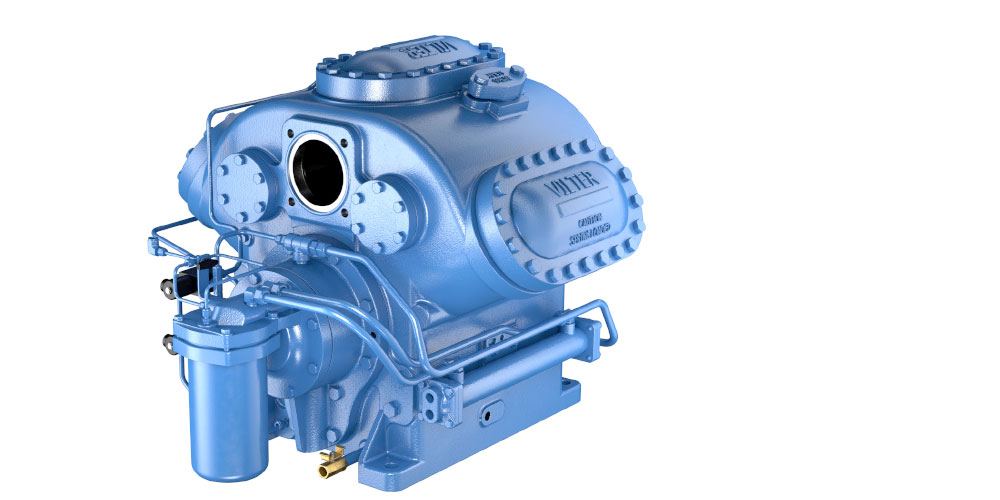

Top End

- Suction and discharge porting achieves minimum pressure drop with valve plates

- Spring loaded safety heads relieve internal cylinder pressure if subjected to an incompressible fluid

- Three compression rings and a single, special oil scraper ring for keeping oil consumption to a minimum

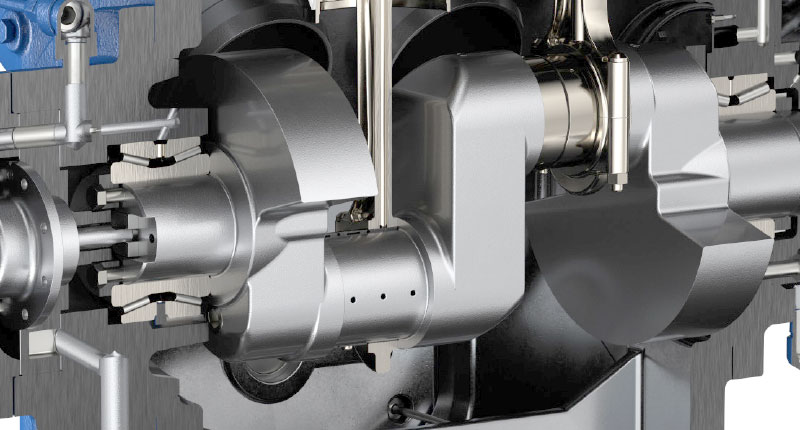

Piston and Connecting Rod

- Piston and connecting rod assembly allows for movement only between the connecting rod bushing and piston pin

- Rod bearings specially designed to supply lubrication to the piston pin bushing at all times

Crankcase

- Double tapered roller bearings enable the compressor to be used for high suction pressure applications

- Double bellows shaft seal assembly consists of two opposed seals – one sealing from the atmosphere and the other from the crankcase

Tri-Micro™ Oil Filter

- Allows full flow of oil at all times, resulting in reduced wear on compressor components

- Enclosed in a seamless drawn carbon steel shell with cast iron cover

- Removes 95% of contaminants as small as 3 microns in size, with the convenience of a throw-away recharge element

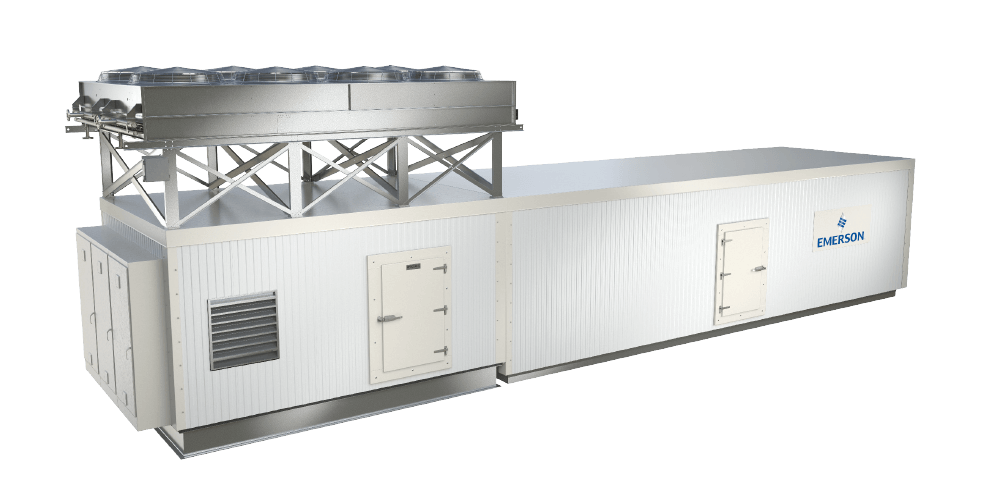

Modular Refrigeration Unit (MRU)

- Used for retrofits, expansions, or new construction

- Eliminates the need for central machine rooms that take up valuable space for operations

- Arrives factory assembled with tested components for easy field rigging and installation

- Cascade system requires less than 100 pounds of NH3 per refrigeration circuit

- Entire structure is certified for seismic events and hurricane force winds

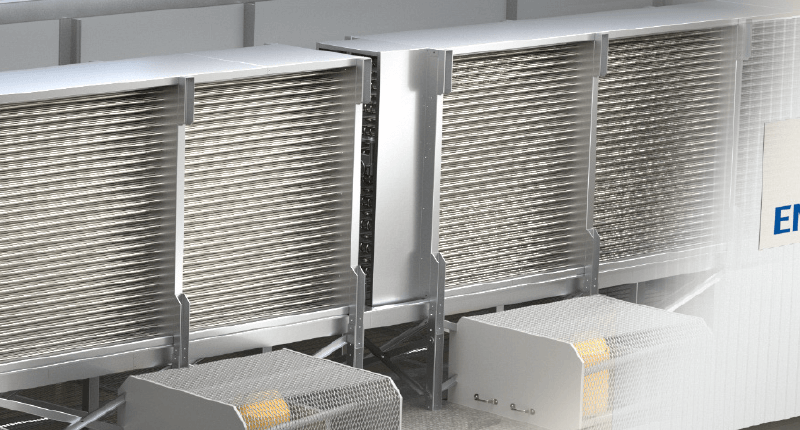

Evaporator

- Two separate coils and sets of fans housed within a separate penthouse enclosure

- Evaporator room attaches directly to the engine room with minimal effort

- CO2 compressors provide hot gas to defrosts the coils, keeping NH3 out of the cold space

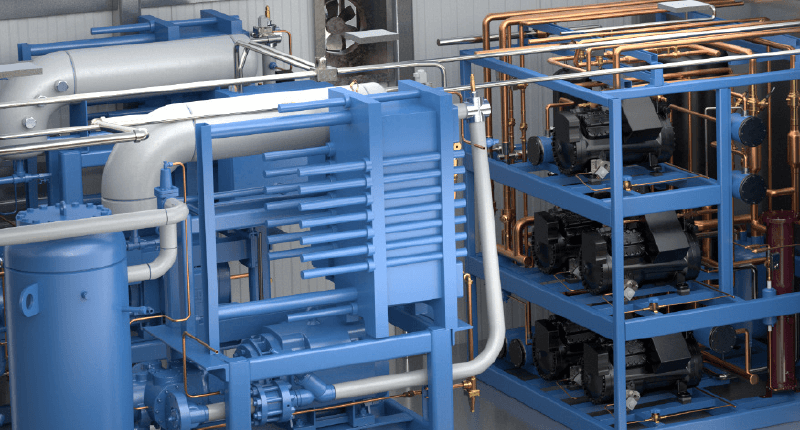

Engine Room

- One standard size engine room for all capacities

- Separated, parallel NH3 skids allow for ease of maintenance

- CO2 skid contains and number of Vilter and Emerson CO2 components

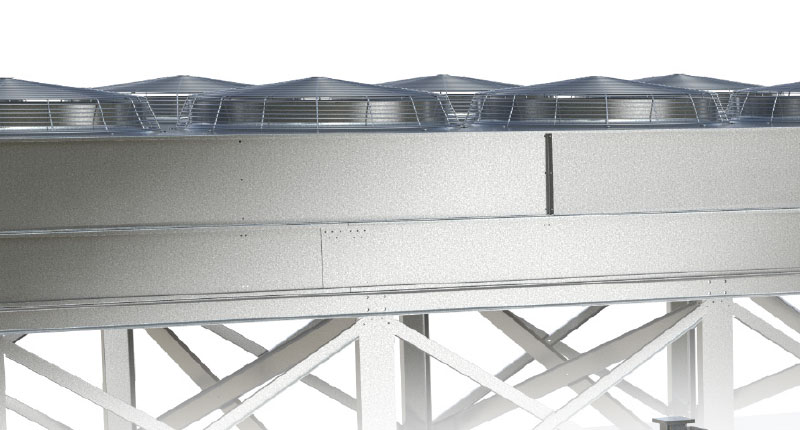

Condenser

- Air cooled condensers eliminate water and sewer costs (For the warmer climates, adiabatic condensers can also be supplied)

- For applications requiring multiple units, a large fluid cooler design (such as glycol) can be utilized with plate style ammonia condensers

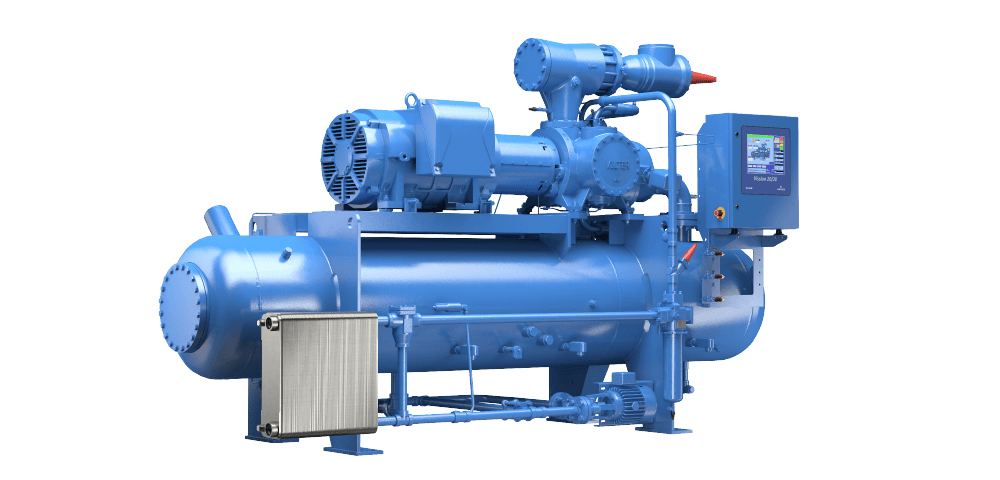

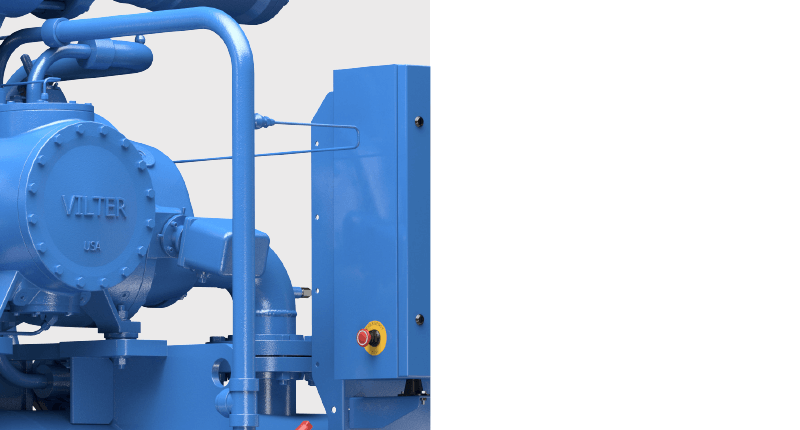

VSS

- Better energy efficiency than twin screw compressors

- Balanced design results in ultra-low bearing loads with significantly decreased vibration and sound levels

- Pre-engineered standard designs, resulting in faster lead times

Parallex™ Slide System

- Part load efficiencies which are far superior to twin screw compressors

- Capacity and volume slides (with an expanded volume ratio of 1.2 to 7.0) move independently of each other based on load

- Eliminates over/under compression and saving energy costs

Vission 20/20 Control

- Reliable operation

- Enhanced communications

- Easy to use

- Flexible and expandable

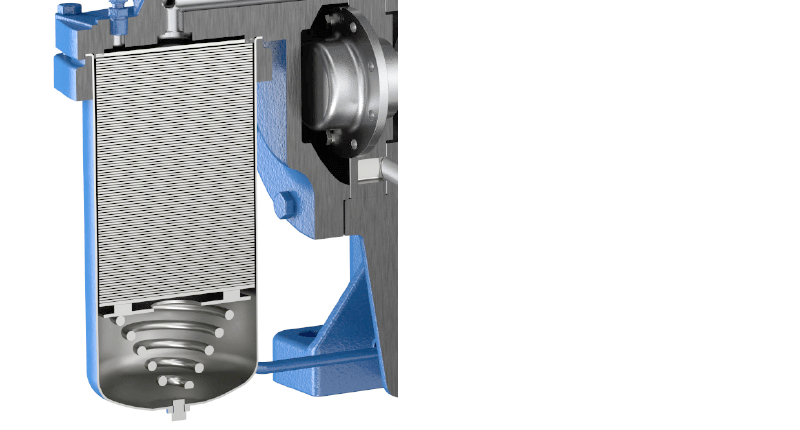

Ultra Fine Oil Filter

- Maximum filtration without flow restriction for extended bearing life

- Longer maintenance interval

Optional Oil Pump

- For units needing constant oil pressure, such as booster, swing and low pressure differential applications

- Positioned conveniently for the service technicians and field operators

Español

Español